Additional Information

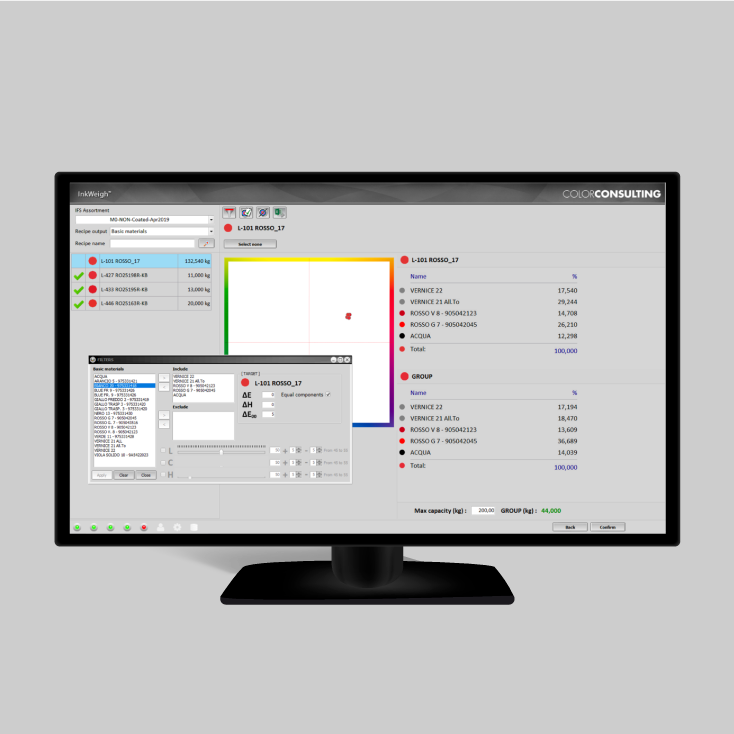

InkWeigh Leftover

The InkWeigh Leftover module allows the correct management of the leftovers, tracing the returned inks and making them available to the InkWeigh system. Leftovers can be used in place of new inks, where appropriate, reducing the cost of the recipe, the quantity of inventories and the need for storage space. The module uses a unique technology on the market that combines the mathematical calculation of machine returns with the colorimetric method.

Description

Features and benefits

- Simplifies the workflow by weighing and correcting recipes in a guided and error-proof process

- Reduces ink overproduction errors with dosing recalculation in the event of an error

- Provides quick access to data and allows the export of reports such as: consumption per job, leftovers used in production, and warehouse inventory

- Guarantees a high return on investment through savings on inks due to the ability to manage and use leftovers in formulation. This innovative solution combines mathematical calculation of returns based on the recipe and the colorimetric reuse method based on the color of the leftovers. (Leftover Module)

- It keeps track of production batches of ink and all the materials used during the printing process (colorants, solvents, additives, etc.) for full traceability to protect consumer safety, particularly in the food, pharmaceutical and similar sectors. (Traceability Module)