The solution allows you to automate achieving absolute color matching between presses, between shifts, and between plants because:

- it improves quality control and analyzes your production data

- it accelerates and improves on-press ink correction

- it organizes and manages your ink inventory

- it reduces and optimizes your machine returns

The solution was developed to help printers achieve and maintain their quality goals.

what can we do for you?

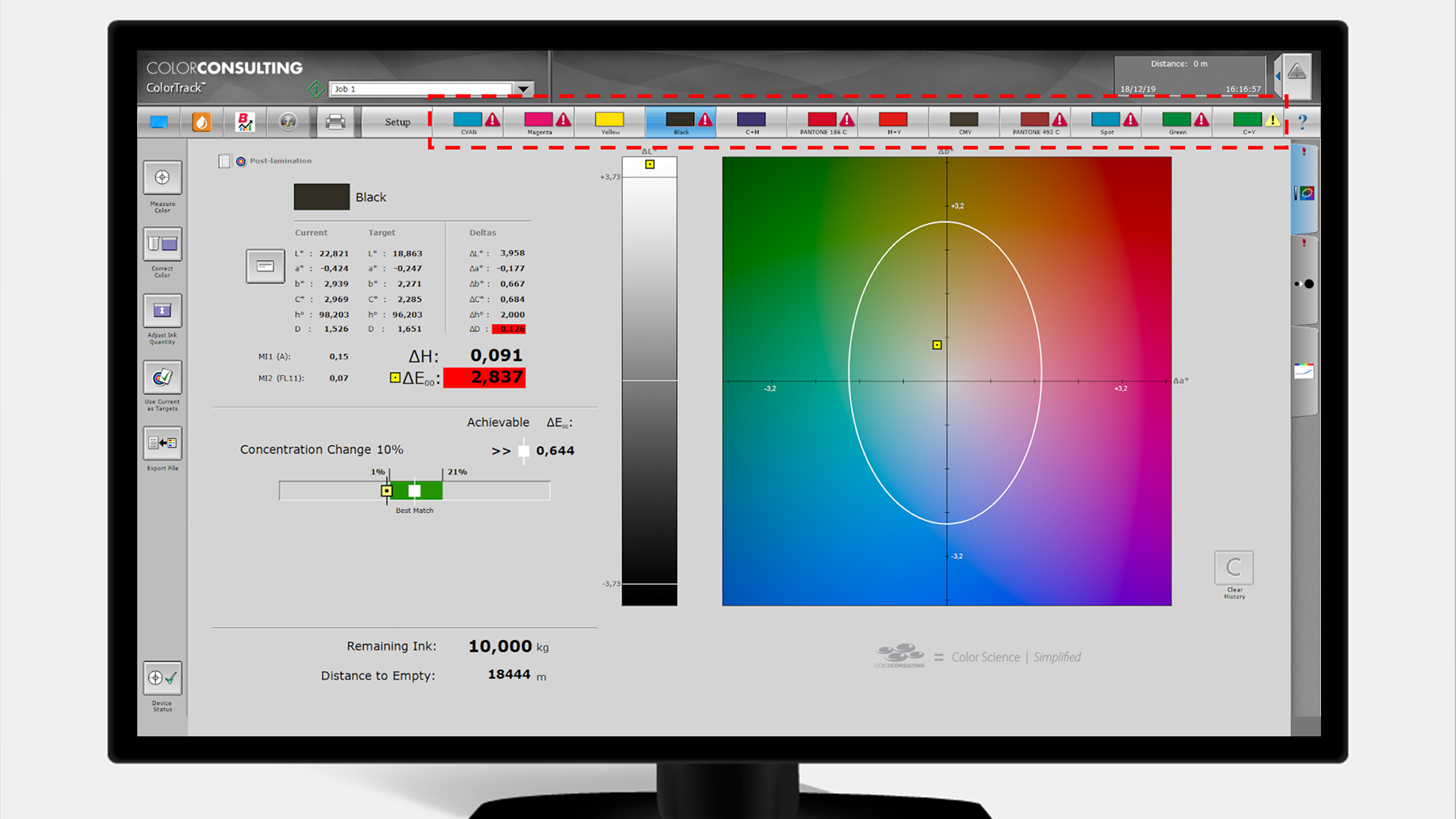

ColorTrack QualityTrack

It allows you to organize jobs by digitizing targets and tolerances, and tracking production by saving all measurements taken for a specific order or reel produced.

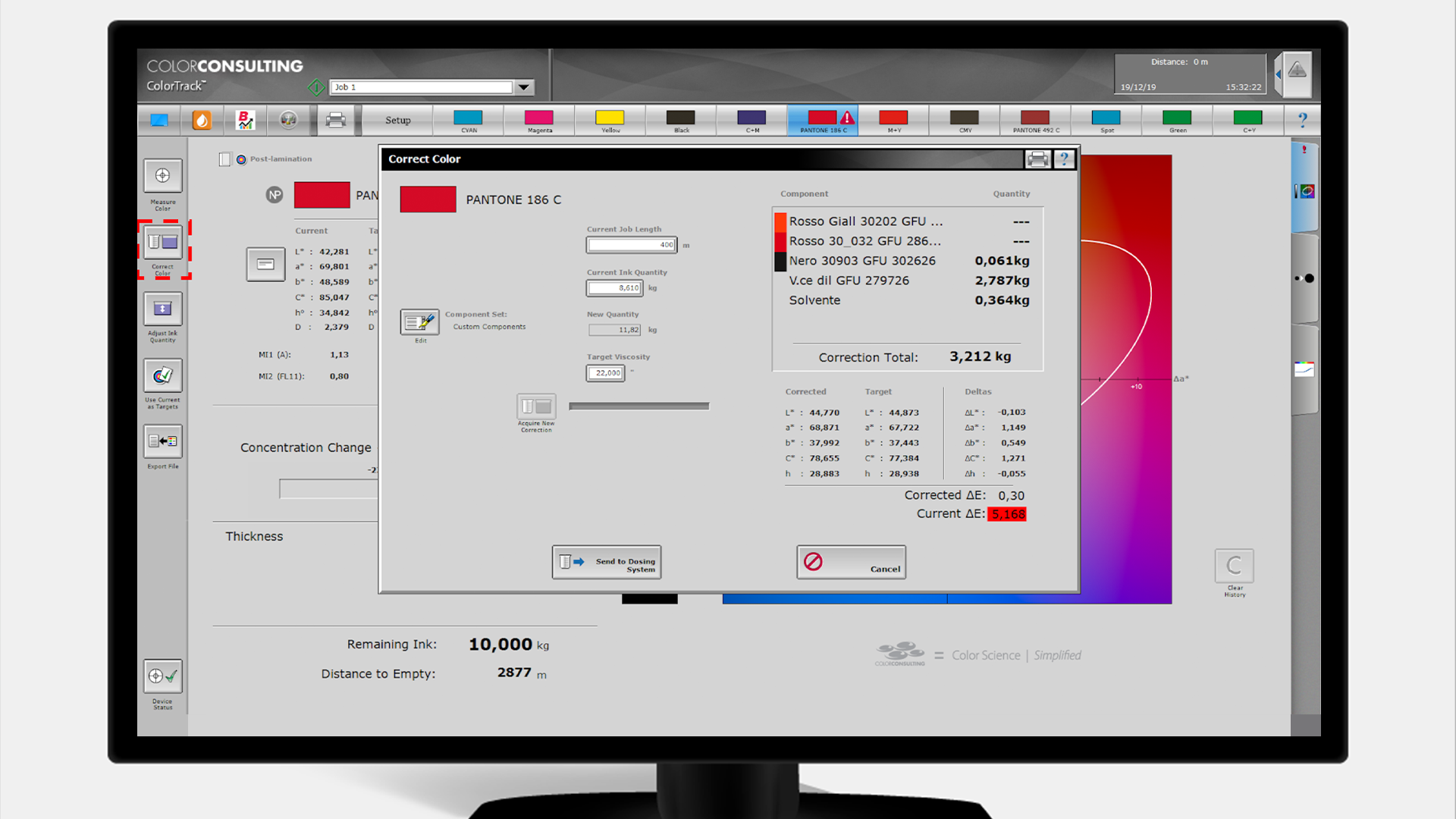

ColorTrack InkCorrection

It completes the management of the entire print color workflow by integrating with the formulation software database and enabling print-side ink correction.

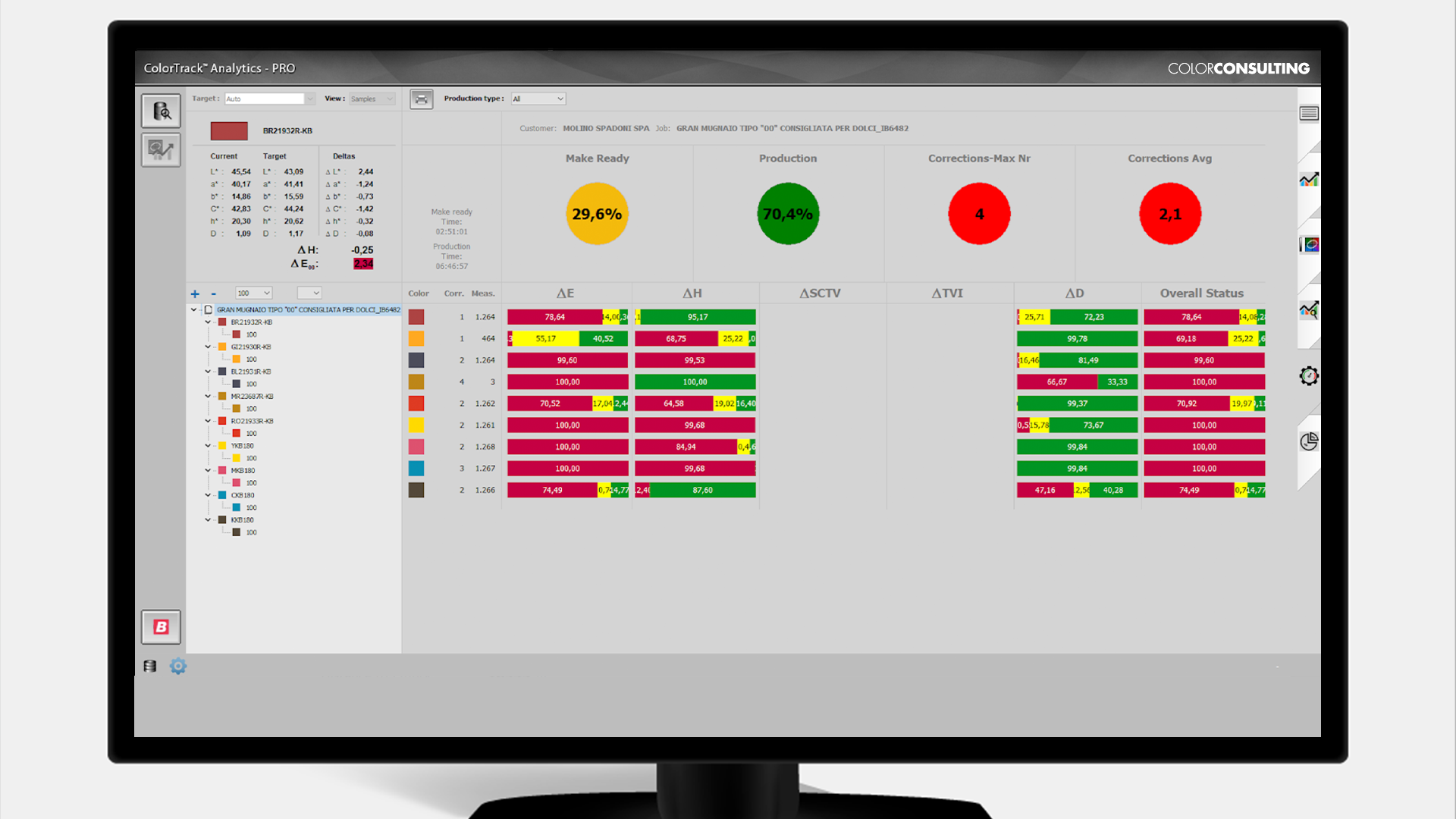

ColorTrack Analytics Pro

It allows you to assess print quality trends and export live production data at any time.

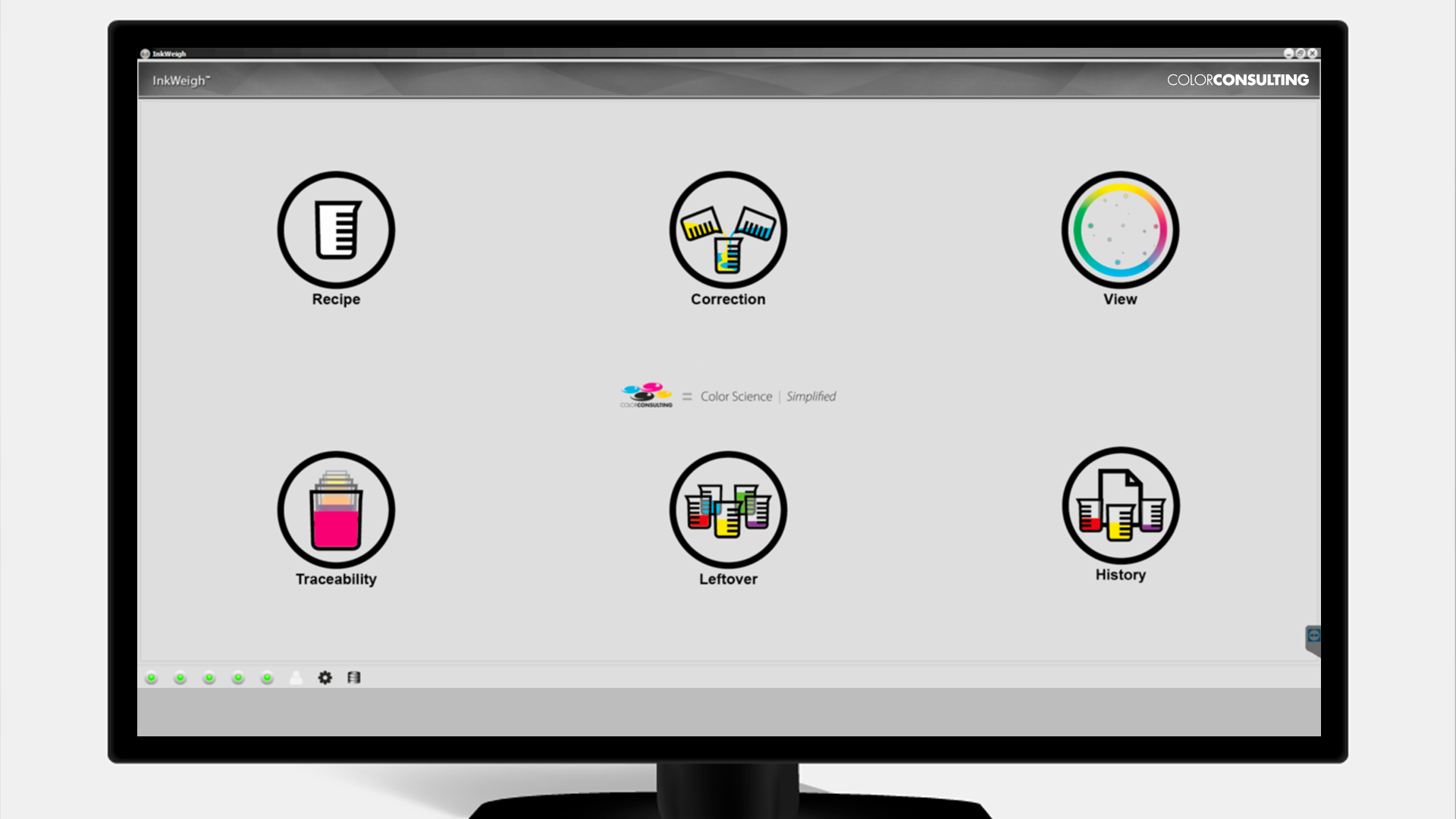

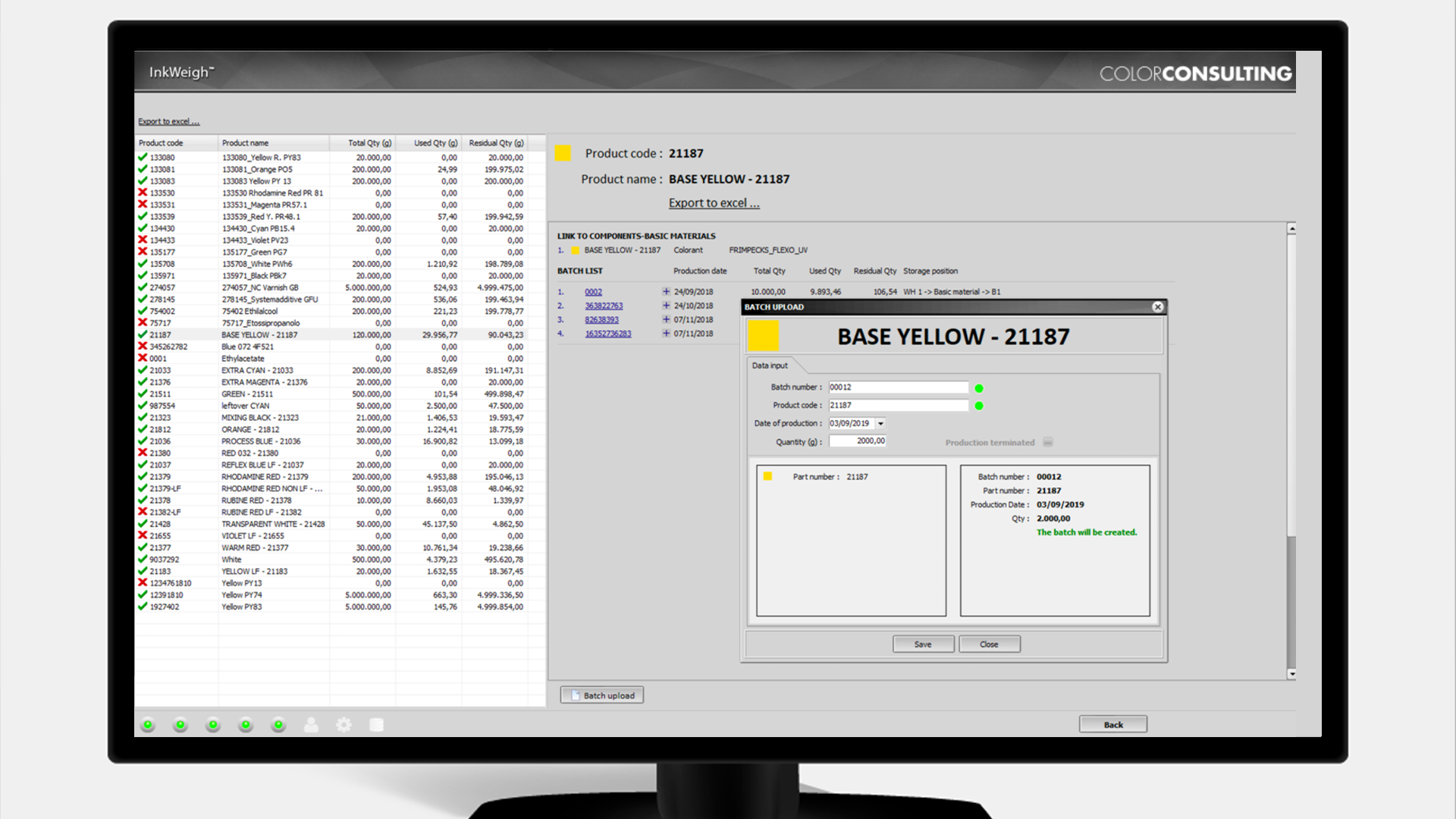

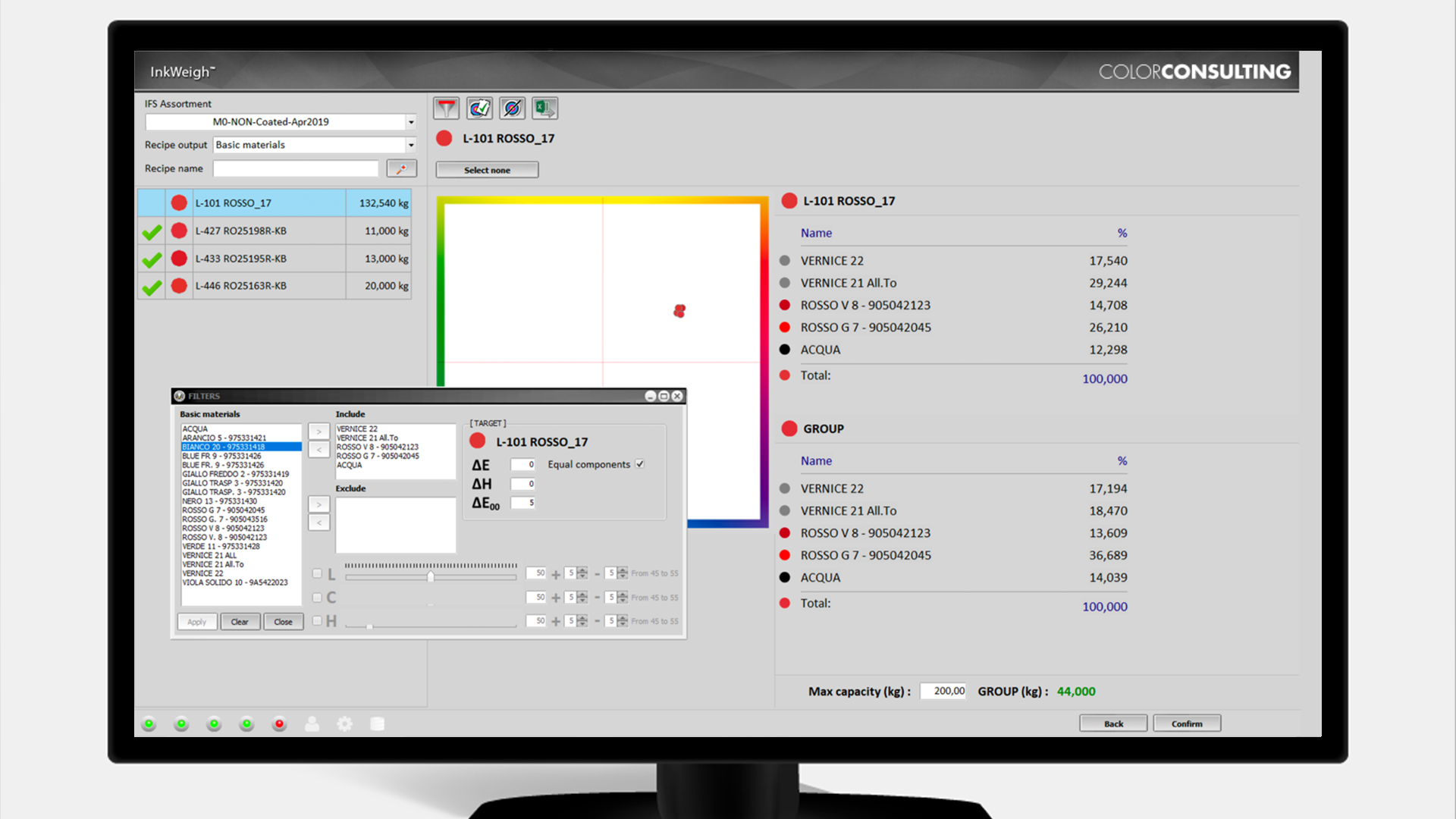

InkWeigh

InkWeigh is a complete ink management solution that allows you to weigh the initial recipe quickly, easily and accurately, in the color kitchen or at the machine.

InkWeigh Traceability

Allows the loading of incoming materials by specifying production batches and keeps track of them by prohibiting their use if the source is not specified.

InkWeigh Leftover

Enables proper management of machine returns by tracking returned ink & making it available for the InkWeigh system. The module uses technology unique in the market.

Why choose

color software suite?

Designed for Printers

The only suite created and developed with the goal of helping printers achieve and maintain their quality goals.

Quality Controlled

It automates the achievement of absolute color matching between presses, between shifts, and between plants because: it improves quality control and analyzes your production data, it accelerates and improves on-press ink correction, it organizes and manages your ink inventory, and it reduces and optimizes your machine returns.

REQUEST TO PARTICIPATE IN AN ONLINE PRESENTATION

DEDICATED TO THE SOLUTION

Talk to us about your needs, your doubts, we will be happy to be able to have our say

and help you grow both technologically and professionally in the field of color control and optimization.

Ask for a free quote and you will be contacted by the company as soon as possible.