Additional Information

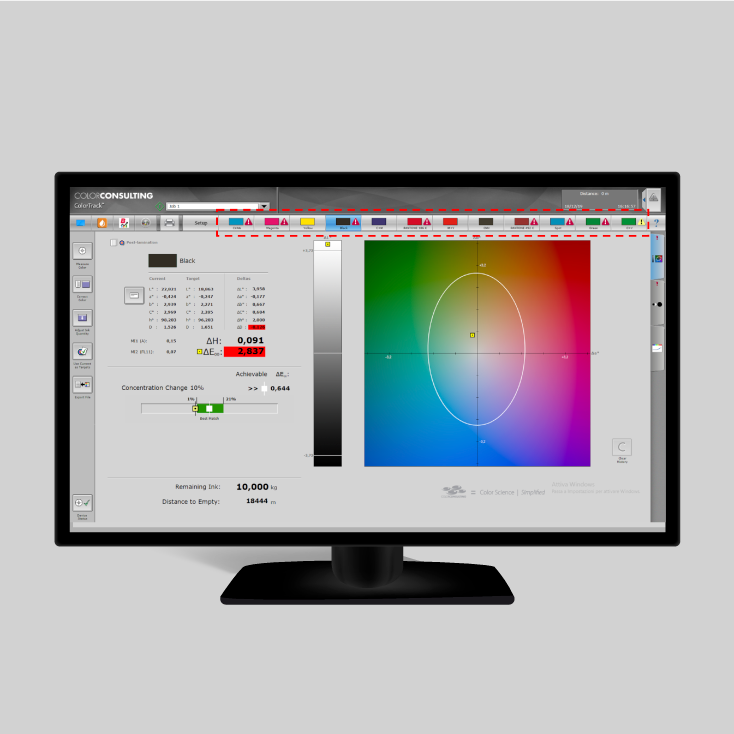

ColorTrack QualityTrack

ColorTrack QualityTrack allows you to organize jobs by digitizing the targets and tolerances, and monitoring production, saving all the measurements taken for a specific order or roll produced.

Description

Some unique features of ColorTrack QualityTrack

- It improves the coordination of the departments thanks to the digitization of all references and tolerances, for each job and customer, in order to ensure repeatability and remove any ambiguity in customer requirements.

- It allows the sharing and control of data even in different production plants.

- It improves job traceability by creating a link between the measurements performed during the print run and the substrate used (batch, roll or sheet number).

- It guarantees the saving of all measurements during the production phase and, with the help of the ColorTrack Analytics Basic software, allows data analysis and the implementation of a continuous improvement process.

- It allows the verification, even after some time, of the work carried out and can export all data for the creation of reports, which allows you to demonstrate the quality achieved in the event of disputes.

- It harmonizes the color libraries, helping to remove duplicate color targets and streamlining the operator experience.